- Jiangxi Dongsheng Plastic Industry Co.,Ltd.

-

Nanchang, Jiangxi, China

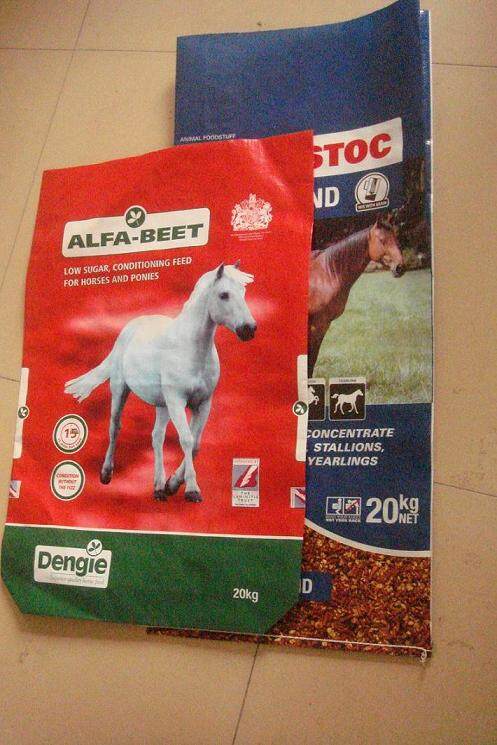

- Main products: ad*star cement bag, block bottom valve bag, Ad Star cement valve bags, Ad Star polypropylene bags, Ad Star box-shaped bags , paper bags for cement, PP sacks / bags with valve, polypropylene fabric, BOPP woven polypropylene bag, Ad Star valve bags, BOPP Laminated PP Woven Bags – Single Side, BOPP Laminated PP Woven Bags with Liner, BOPP Laminated PP Woven Valve Bags

-

Tony

Hi there! Welcome to my shop. Let me know if you have any questions.

Tony

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

How to get more accurate big bag prices

2022-10-17 15:11:35

So, you can see, that customized samples have to go through the same process as producing large shipments but add some extra waste.

For a customized sample, pls kindly let us know the following information:

1. The size of the bags/sacks: Length * Width * Thickness(Side Gusset Depth)

2. The fabric thickness

3. The printing effect

4. In case any other needed like hemming, double stitching, easy-open, inner liner…

5. The quantity

If it is possible, samples will be the best for clarifying, if not, we will recommend relevant bags/sacks with details for your evaluation.

* The total Customization cost=customization unit price(subject to different specifications) * quantity print plate creating cost.

For the Packaging bag samples, we provide 3 solutions:

1. Available stock samples

According to your requirements, we provide our stock samples that are similar to your size, thickness, and print method, you can check the bag loading capacity and our printing quality.

2. A semi-customized sample

In case we have the proper yarn/tape, we can weave some fabric for you specially and make the correct bag sample for you. Along with that, provide separate samples with the same printing method.

3. If exactly the same samples are necessary

Without charging any material costs, the production of packaging bags requires a total of 6-7 progress, and each progress requires 2-3 workers. First, to debug the machine, which will take more than 30 minutes, for block bottom valve bag samples, a half-day is normally needed. So the labor cost will be very high.

Plus the print testing with several hundreds of fabric to start(because the machine is large and long, otherwise, it can not be started). And alignment of the print plate, color tuning, so waste is much bigger.

-

Polypropylene Sacks PP Woven Bags

-

Dry ice packaging film packing bag pearlized bopp plastic film

-

Fertilizer color printing woven bag water-soluble fertilizer compound fertilizer mixed fertilizer bag slow-release fertilizer nutrient soil

-

Fertilizer color printing woven bag water-soluble fertilizer compound fertilizer mixed fertilizer bag slow-release fertilizer nutrient soil

-

Wholesale Plastic Waterproof PVC Steel Wire Frame Duvet Comforter Pillow Bedding Storage Packaging Bag for Home Textile Storage Bag

-

Nutritious soil special PE bag uniform fertilization convenient packaging

-

Nutritious soil special PE bag uniform fertilization convenient packaging

-

Nutritious soil special PE bag uniform fertilization convenient packaging

-

Nutritious soil special PE bag uniform fertilization convenient packaging

-

Nutritious soil special PE bag uniform fertilization convenient packaging

-

Nutritious soil special PE bag uniform fertilization convenient packaging

-

Nutritious soil special PE bag uniform fertilization convenient packaging

-

Nutritious soil special PE bag uniform fertilization convenient packaging

-

Supply manufacturers fertilizer PE bag water soluble fertilizer compound fertilizer bag

-

Supply manufacturers fertilizer PE bag water soluble fertilizer compound fertilizer bag

-

Supply manufacturers fertilizer PE bag water soluble fertilizer compound fertilizer bag

-

Supply manufacturers fertilizer PE bag water soluble fertilizer compound fertilizer bag

-

Supply manufacturers fertilizer PE bag water soluble fertilizer compound fertilizer bag

-

High-strength fertilizer packaging bags, wear-resistant and pressure-resistant, enhance efficiency and provide protection.

-

Customized soft packaging bentonite cat litter and various microbial agents for moisture-proof and water-proof purposes.

-

Customized soft packaging bentonite cat litter and various microbial agents for moisture-proof and water-proof purposes.

-

Fertilizer color printing woven bag water-soluble fertilizer compound fertilizer mixed fertilizer bag slow-release fertilizer nutrient soil

-

Fertilizer color printing woven bag water-soluble fertilizer compound fertilizer mixed fertilizer bag slow-release fertilizer nutrient soil

-

Fertilizer color printing woven bag water-soluble fertilizer compound fertilizer mixed fertilizer bag slow-release fertilizer nutrient soil